Standard Rate Control Standard Rate Control

Set spread width and flow rate for precise material distribution, enabling operators to monitor and adjust application levels. |

Job Tracking Job Tracking

Track material usage on every job site directly from the controller for customer billing, proof of service, and material supply planning. |

Future-Ready Future-Ready

Compatible for future BOSS Smart Connected material management solutions and products |

Simplified Material Calibration Adjustment Simplified Material Calibration Adjustment

Enables operator precision in material flow control |

Controller Operated LED Lighting Controller Operated LED Lighting

Upgraded LED brake lights, work lights, and selectable patterned beacon lights ensure operators are easily seen. |

Motor Performance Motor Performance

Upgraded feeder system efficiency and increased spinner power sets new standards beyond the traditional VBX Series. |

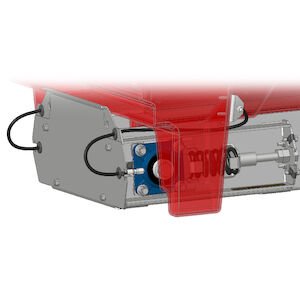

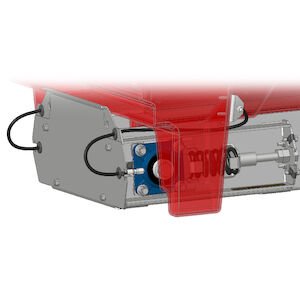

Remote Grease Zerks Remote Grease Zerks

Remote grease zerks for enhanced maintenance and serviceability |

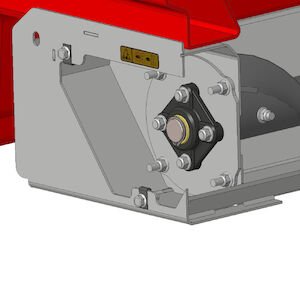

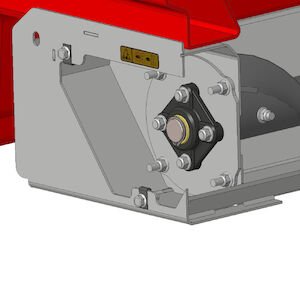

Easy Access Hatch Easy Access Hatch

Facilitate easier access to the motor, enhancing overall serviceability. |

Urethane Spinner Urethane Spinner

for durability and maximum adjustability and spreading efficiency. |

Standard Tarp System Standard Tarp System

VCP tarp with bungee tie-downs comes standard on all VBX spreaders to protect spreading material from the elements. |

Reinforced Poly Hopper Reinforced Poly Hopper

Reinforced poly hoppers offer capacities of 1.5, 2, and 3 cubic yards, designed to elevate efficiency and productivity to meet your needs. |

VBX+ Overview VBX+ Overview

Discover the standard smart features, as well as the updated and new features that differentiate it from BOSS' previous VBX line and competitors. |

Advanced Auger System Advanced Auger System

Auger Poly Bearing eliminates the need for greasing, reducing downtime and improving ease of use. |

Standard Rate Control

Standard Rate Control Job Tracking

Job Tracking Future-Ready

Future-Ready Simplified Material Calibration Adjustment

Simplified Material Calibration Adjustment Controller Operated LED Lighting

Controller Operated LED Lighting Motor Performance

Motor Performance Remote Grease Zerks

Remote Grease Zerks Easy Access Hatch

Easy Access Hatch Urethane Spinner

Urethane Spinner Standard Tarp System

Standard Tarp System Reinforced Poly Hopper

Reinforced Poly Hopper VBX+ Overview

VBX+ Overview Advanced Auger System

Advanced Auger System