Westernplow DROP™ 250

|

PLACE SALT EXACTLY WHERE IT’S NEEDED When precision is needed with salt placement, the new line of stainless steel drop spreaders from Western Products is the answer. The Drop 250 and Drop 600 spreaders provide up to 36″ of spread width in a drop pattern so the salt stays exactly where your vehicle drives. And with three mounting systems, these units can fit on most UTVs, compact tractors, or wheel loaders to make quick work of sidewalks, walking paths, and other paved surfaces where truck equipment can’t easily gain access. |

|

The new Drop 250 and 600 are constructed of laser-cut stainless steel and high strength rivets. The oil filled poly bearings provide a long, maintenance-free service life. |

|

The material delivery system has finger-like appendages that agitate the surrounding material with every revolution. This ensures a consistent amount of material flows into the spreader trough and, at the same time, keeps it from bridging. |

|

The entire trough drops open for easy and fast material clean-out when the job is done. This allows you to store any leftover de-icing material in a dry, weather-resistant container until you need it for the next job. |

|

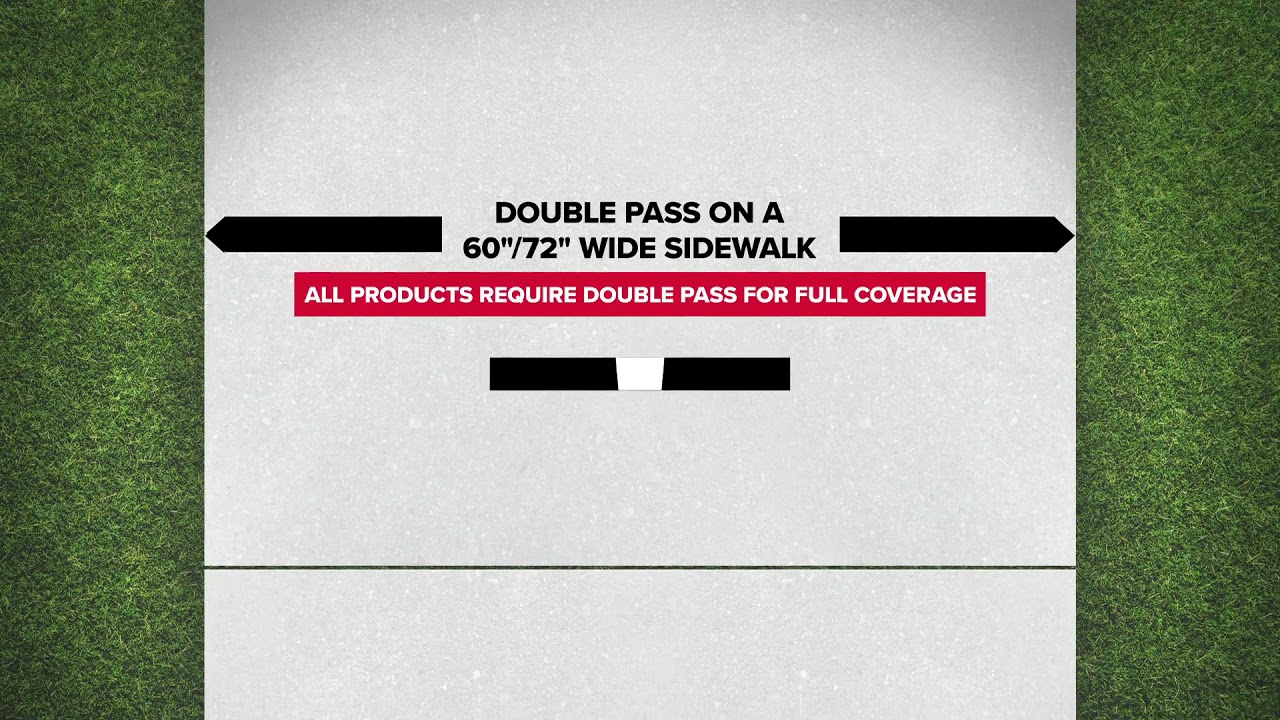

A 36″ spread width makes applications on sidewalks and walking paths easy. The WESTERN drop spreaders can treat these surfaces with one or two passes and limit damage to the grass or sensitive surfaces right next to the path. The spread width can be limited to 30″ by activating 3″ baffles on either side of the trough. |

|

The salt is protected by a custom-molded polyethylene lid that is secured by rubber straps. |

|

A stainless steel hatch screen helps break up de-icing material to prevent bridging and clogs during operation. A hinged bag splitter that easily pulls up to open bagged rock salt for easy loading. When not in use, the bag splitter can be folded down and out of the way. |

|

Match material delivery rate to the precise conditions with enhanced speed control with a single variable-speed control knob that controls material flow rate. |

|

A detachable 2-inch receiver style mount is provided as a standard feature and includes all the necessary hardware to attach the spreader to the vehicle. This allows the spreaders to be mounted on various equipment; anything with a 2-inch hitch receiver with sufficient payload capacity for the selected spreader. Included With New Spreader Purchase |

|

The 3-Point Mount includes all the pins needed for installation and is intended for compact tractors and articulating loaders. The spreaders have been designed to include attachment points and hardware that are compatible with a 3-point style implement hitch. This style of attachment is common on tractors but can also be found on some other types of equipment as well. Included With New Spreader Purchase |

|

The spreaders were designed with in-bed mounting in mind where the units can sit flat and balanced. Brackets and ratchet tie down straps are included to establish correct positioning and to secure the unit in the bed of a UTV. This type of installation reduces stress on the equipment since the weight is positioned over the rear wheel as opposed to behind them and allows for additional versatility to maneuver in tight spaces. Included With New Spreader Purchase |

| Full Line Brochures | Download |